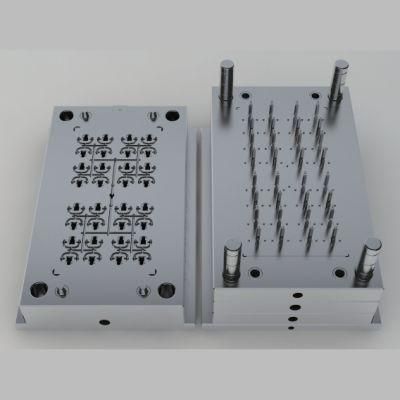

Infusion Set Injection Mold

Shanghai Best Hope Precision Device Co., Ltd.- Type:Infusion Set

- Material:Plastic

- Ethylene Oxide Sterilization:Without Ethylene Oxide Sterilization

- Quality Guarantee Period:Two Years

- Group:Adult

- Logo Printing:Without Logo Printing

Base Info

- Transport Package:in Poly Bag

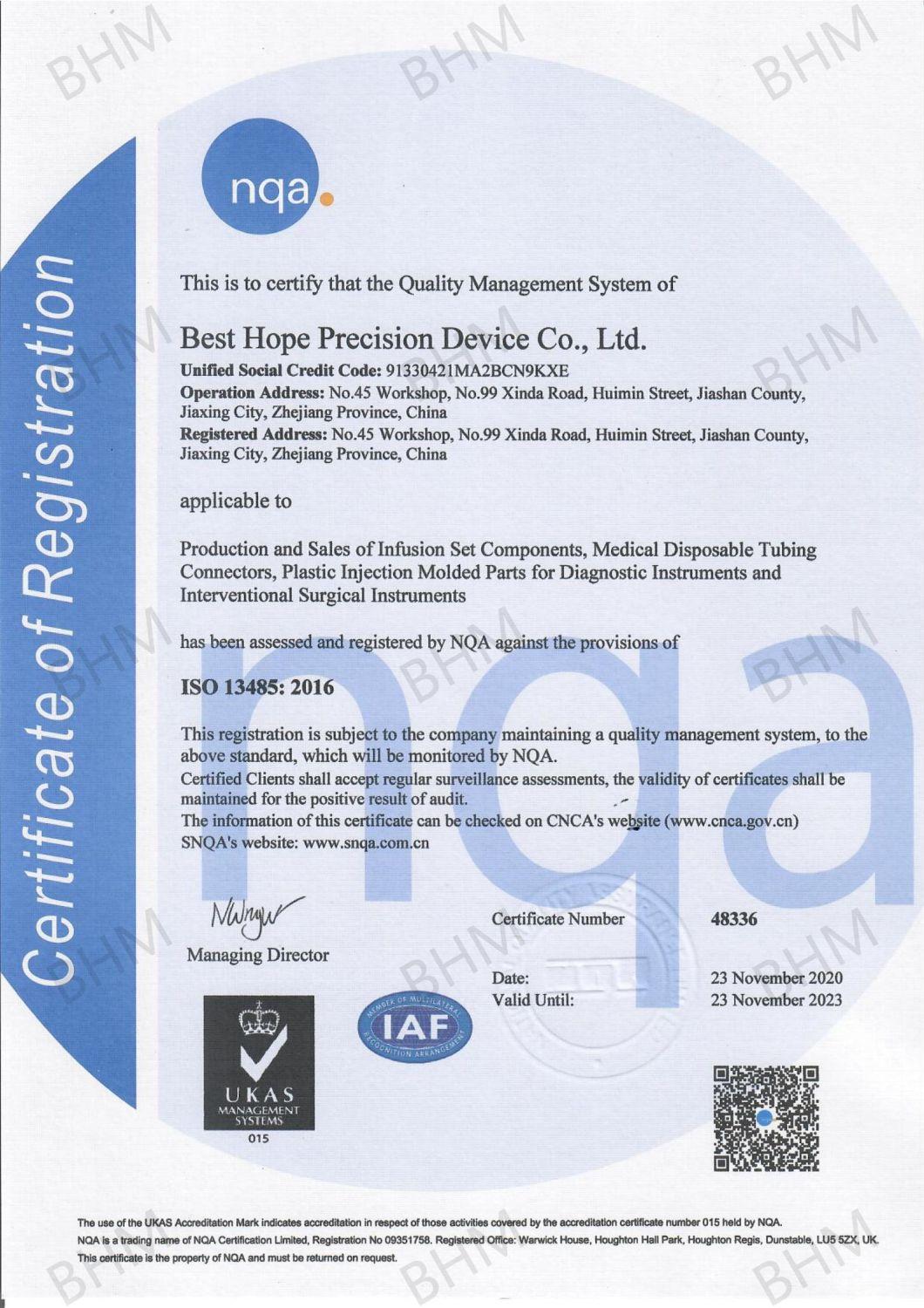

- Specification:ISO13485 2016

- Trademark:BHM

- Origin:China

- HS Code:3926909090

- Production Capacity:as Customers′ Requests

Description

Basic Info.

Transport Package in Poly Bag Specification ISO13485 2016 Trademark BHM Origin China HS Code 3926909090 Production Capacity as Customers′ RequestsProduct Description

Mold Specifications:| Description | Plastic injection mold for infusion set |

| Part Material | all thermoplastics such as ABS, PC, PP, PE, PA, TPE, POM, PPS, PBT and other high engineering plastic, such as PEEK, PPS, PPO, PEI, PES etc |

| Cavity number | 1/2/4/8/16/32/48/64...(optional) |

| Runner | Hot runner or cold runner |

| Core & cavity material | S136, 1.2083 stainless steel |

| Mould Standard | MISUMI, DME,CUMSA,HASCO |

| Mould life | Long mold life |

| Available format | .stp/.pdf/.x-t/.step./.dwg/.dxf/.igs/.prt/.stl/.sldprt |

About Us:

We, Best Hope Mold & Plastic is an ISO13485 certified manufacturing factory, specializing in precision mold design, manufacturing and high-end plastic injection molding processing. Focusing on precision tooling of Medical Devices moulds, with rich experience in medical products.

Products Range:

Medical moulds from regular medical disposables to high precise minimally invasive devices, Communication Parts, Household Appliances Parts, Electronics Parts, Cosmetics Parts etc.

Our Capabilities:

- Engineering design

-mold design

-flow analysis

-CAD/CAM

Our sophisticated designing team with decades of experience can provide the most appropriate design and manufacturing option for your product, ensure your product is put into production quickly and efficiently.

- Mold build

-pilot mold and tests

-production mold

-mold for export

-complex mold solution

All our tools are built right here in our own facility. Our modern, fully equipped tool shop is capable of producing tools to the highest SPI standard. We also have a team of full-time toolmakers who are capable of taking your tooling from concept to finished mold.

- Custom plastic molding

-ISO13485 management

-high and low volume running

-medical masterbatch

- Post molding services

-printing

-packaging

-sterilization

Our Strengths:

Rich experience in medical products, design and develop molds against ISO standard

Good quality from a small spare part to a whole mold tooling

In-House Tooling Workshop make sure on time delivery

Working Process:

I. Order Confirmation and Advance Payment

II. Make DFM report, Mold Design 2D, 3D send you for approval

III. Order material, make the time schedule; weekly progress photos and process to you. Project engineer take charge of the manufacturing.

IV. Send T1 Mold Samples to you for evaluate, Part Inspection Report

V. T2 Mold trial, recheck the part dimensions

Mold Shipment:

1. Test the mold before shipment

2. Mold Inspection, take photos of mold

3. Spare parts, mold drawings packed along with mold in wood box

BHM at Medical Exhibition:

Every year we attend international medical exhibitions for example CMEF,MEDICA, Arab Health, FIME etc.